About Us

Our Factory

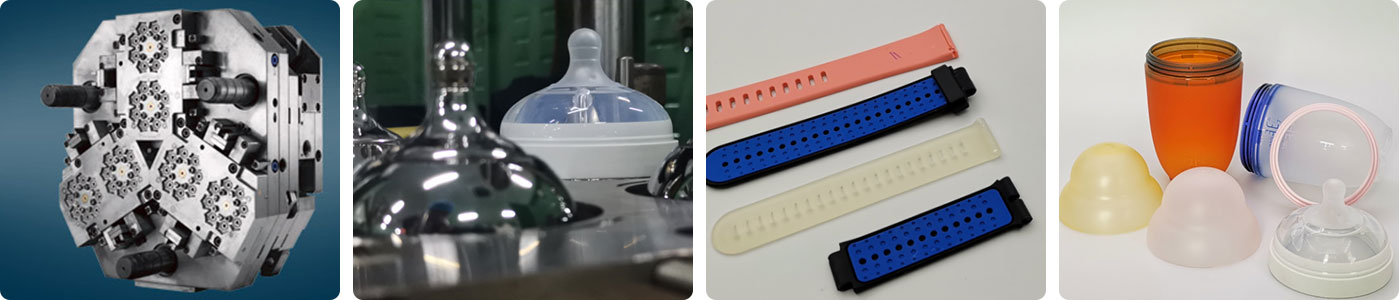

After more than ten years of development, the business demand of Jvtech is increasing day by day. In order to meet the demand, in 2021, a fully automatic liquid silicone molding OEM factory was established, and we always pursue to provide customers with precise liquid silicone components and products with exquisite technology. With world-class high-performance liquid silicone components, unique professional Baby Eating Bib mold making and LSR Soft Infant Finger Toothbrush, and close cooperation with high-end technical support partners, we have established a diversified customer base to provide comprehensive silicone product solutions for medical, personal care, automobile, maternal and child industries.

In order to ensure stable and high-quality service for customers, Jutai Technology has continuously improved its business management level and product quality management system, and has implemented enterprise resource planning (ERP) and ISO series qualification certification, which are the best manifestations of its commitment to customers. ISO13485 qualification certification and QS certification obtained in 2015. The main service scope is the research and development, production and sales of liquid silica gel products. The company's main services include liquid silicone mold, liquid silicone integrated molding, solid silicone molding and other related silicone processing. With the design concept of safety, environmental protection and cost reduction, it provides customers with reasonable customized services to meet the various needs of customers for silicone products. Products are all over the world. The company has always been committed to the pursuit of high-quality project delivery, committed to becoming a reliable LSR technology supplier, with R&D investment, delivery speed and perfect service quality, in order to enable customers to achieve highly competitive products to achieve the ideal sales target. We support free proofing for mold opening. We are willing to let customers know about us first, grow together and achieve win-win cooperation!

Our Factory

Zhongshan Jvtech Silicone Technology Co., Ltd. is located in Building A, Shouli Industrial Zone, Renmin Street, Torch Development Zone, Zhongshan City, Guangdong Province, China. Since the establishment of the factory in 2010, it has more than ten years of experience in professional production of LSR molds and molding, and the cooperation projects occupy a leading position in the same industry. We are committed to providing silicone and plastic molding technology solutions for many industries. Machinery and raw materials are selected to cooperate with well-known brands at home and abroad, with 100,000-class dust-free workshop, dust-free LSR automatic production workshop, baking workshop, high-standard mold workshop and high-precision independent laboratory. Strictly implement the national standard and European standard to control VOC, fully implement the ISO9001 quality management system standard, and insist on the requirement of training before taking up the post. The complete quality control system is for quality, so that customers can deliver with peace of mind!

Our Product

Our Products includes the following:

1. LSR Mold

2. LSR molding

3. Silicone products processing

4.Bi-color injection molding

5.P+R molding

We supply LSR products all over the globe to a wide range of companies worldwide, ranging from large multinational organizations to small individual companies.

Our Certificate

Production Equipment

The company has a research and development team with 10 years' experience, and the production equipment used are all from first-line brands at home and abroad: a modern assembly line consisting of 60 LSR injection molding machines and a series of supporting automation machinery, which, with perfect and scientific management mode, can well meet the various needs of customers for products. We take environmental protection and cost reduction as the design premise, and spend 45% of our profits on research and development every year. Over the years, thanks to the support and love of new and old customers at home and abroad, the products have been exported to Europe and America, the Middle East, Central and South Asia and other dozens of regions, creating a good corporate image and reputation.

Production Market

We have customers from both domestic market and oversea market.Mike Sales managers can speak fluent English for good communication.

| Our main sales market: | |

| North America | 60.00% |

| Western Europe | 12.00% |

| Oceania | 10.00% |

| South America | 5.00% |

| Southeast Asia | 5.00% |

| Mid East | 3.00% |

| Eastern Europe | 3.00% |

| Eastern Asia | 2.00% |

Our Service

According to the customer's drawings or samples. In the early stage, we will have a detailed video communication with you to discuss the feasibility and hidden dangers. After the mold manufacturing is completed, we will hold a video conference for the customer, and make samples for the customer free of charge. When the customer confirms the samples, we will start production. During the production process, we will strictly control the product quality. If there are any quality problems, we will make corresponding compensation, and various liquid molds will be developed to form. The quality and efficiency of the services we provide are very few.

Our enterprise tenet is honesty, which is also an important reason why we are getting better and better.